We built a prototype for a sheet casting tool to accommodate our needs and desires to produce large and evenly flat sheet materials made of bioplastics such as the gelatine and agar-based ones, and the alginate plastics we made last week. We tested the machine by casting a sheet with alginate plastic. So far, the machine functions and we made a lovely 2mm sheet with it (which shrank a bit)l but could be improved by finding a better solution for keep the walls together – the silicon glue didn’t hold. And also the wiper or squeegee could have a deeper wiping edge so the strips can act as walls. Excess liquid will creep up, and could be contained if the wiper sinks a little deeper by default. Anyway, details details. Here's our working prototype!

...

...

@@ -10,10 +10,6 @@ The machine might need some iterations but has potential to allow us to research

We also created an instruction manual to go with the designs for anyone who would like to recreate it.

*The instruction manual designed by Paulina Martina, 2019*

The process of creating the machine was challenging at first (see below), but as soon as we were on the same page and had a shared understanding of the goals, the technical nitty gritty, and names for things, we took off like a rocket and had a lot of fun even though loads of stuff of course went wrong (and got fixed) along the way.

##Feedback

...

...

@@ -36,11 +32,21 @@ After seeing the many interesting machines during the lecture, we were of course

We discussed how some machines are easy to "hack" by changing the end actuator (replacing the knife of the vinylcutter with a pen and similarly, inserting a paint brush into the big milling machine). And we got inspired by looking through the industrial processes listed in the book [*Materiology: The Creative Industry's Guide to Materials and Technologies*](https://www.naibooksellers.nl/materiology-the-creative-industry-s-guide-to-materials-and-technologies-22982.html) by Daniel Kula and Élodie Ternaux that Cecilia suggested.

**Inspiration**

**Research and inspiration**

These are two machines I found that deal with flat materials, but not quite what we were looking for. But it's nice to see the feeding mechanisms I think. If you figure out the feeding, the moving of the material, you figure out half the machine.

*A few machines we studied from the Materiology book*

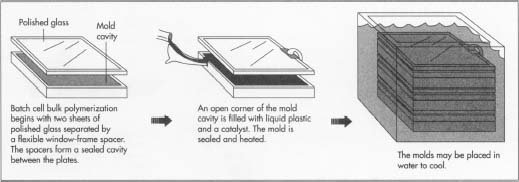

We also looked up how for example acrylic sheets, but they are formed with heat, so that's quite a different process than the bioplastics we've been using because the set as they cool down or as a curing agent is applied. Still interesting though.

*How acrylic sheets are produced, [MadeHow article on Acrylic Plastic](http://www.madehow.com/Volume-2/Acrylic-Plastic.html), 2006*

I was also really into the machines by Shell Works! We watched their video during the lecture.

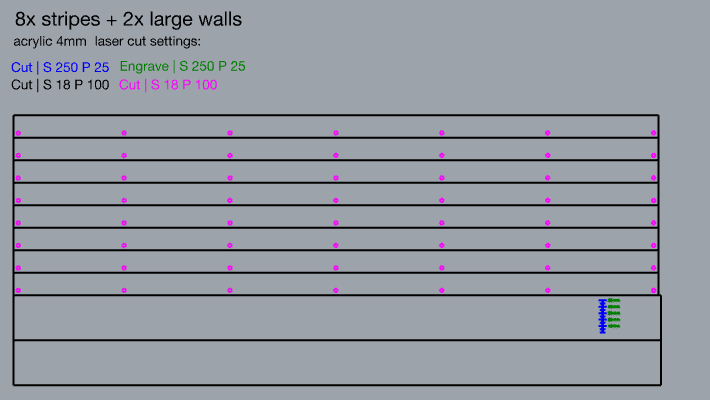

*Cutfiles for the Squeegee2000, Beatriz Sandini, 2019.*

During the cutting process we ran into quite a few hurdles, that we overcame of course. But it was annoying too. Our design file was made in Rhino, exported as .dxf (trying all possible export settings), and using LaserWorks software to send files to the machine. Some issues and their solutions:

* Error message when trying to send job to engrave TEXT to the machine: “polylines not closed”. Solution: > Tools > Unite Lines

...

...

@@ -206,6 +220,10 @@ Cook up a batch of bioplastic and test it!

* The acrylic glue and silicon didn’t hold sadly. But even without it we managed to cast a sheet quite well. We need to find a solution for it but we have something of a working prototype. Maybe designing snapfit connections for the corners of the wall would work?

* Wood might not be the best pick for material because it absorbs liquid, like the calcium chloride you spray onto alginate. We coat treat the wood with a coating to protect it, or make this from a different material.

We are also creating an IKEA style instruction manual to go with the designs for anyone who would like to recreate it.

*Fragment of the instruction manual being designed by Paulina Martina, 2019*