-

Mitalee Parikh authoredMitalee Parikh authored

#Electronics Production This week is about learning how to fabricate a PCB.

Page Summary

- Summary

- PCB fabrication

- Assembling the board

- Testing and programming

- Important and interesting links

- Summary

There a some different options of in-system programmers in the FabAcademy notes. In the AVR family, there are boards based on the the ATtiny45, ATtiny44 and ATmega16U2.

I review all options, and decide to make the ISP based on Brian's design because it seemed simple and straight-forward, and a good one to start with because it has ample documentation. It is called the FabTinyISP.

I used the facilities in FabLab UAE to fabricate the ISP with a Roland SRM-20 milling machine.

I use a double sided FR1 board to mill the ISP, because the lab is out of stock of single-sided ones that are not locally available.

An in-system programmer is basically serial programming that allows programming and reprogramming of microcontrollers, soldered on a target Printed Circuit Board. This week is about learning both, making the PCB from scratch and programming the microcontroller on it to become a programmer itself.

- PCB fabrication Workflow

The PCB workflow basically consists of making png traces/outlines from a design file, or using existing ones > creating toolpaths > prepping a milling machine > loading a copper sheet and endmill > setting origin on machine > milling and then cleaning to solder components before stuffing and testing the board.

Create toolpaths

First step is to download the design files for the traces and the outline of FabTinyISP from Brian's documentation page.

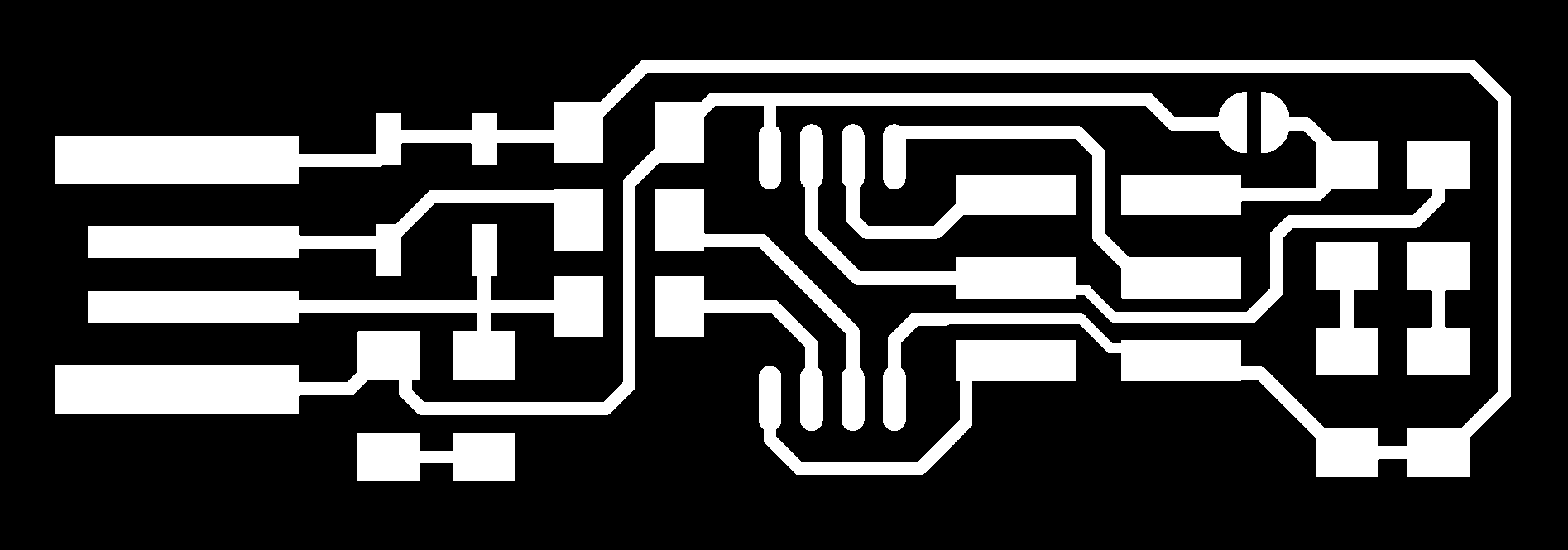

The traces are the thin pipelines that connect the footprints of components.

Traces (1000dpi)

The outline is the outer boundary to be cut. Sometimes it also includes through-holes to be made in the PCBs.

Outline (1000dpi)

It is important to note that both these images are at 1000 dpi resolution in png format.

Next, these png images need to be converted to tool-paths for CNC machines to follow. Fabmodules and Mods both, developed by the Fab community can be used to make the tool-paths. They run in the browser.

But it shows me unclear toolpaths with default settings, for both the traces and the outlines. With random dots being detected arounf the traces.

I'm not sure why these errors occured. I try using FabModules with the same files and same settings. And it works perfectly. So I guess Mods has a different way to read these files.