diff --git a/docs/assignments/week05.md b/docs/assignments/week05.md

index 8e42dbe401e63df5d5e3dee7c44cddb050be35c7..9ed7fb41b9e30d1b74722de8c779c2408bf59c8e 100644

--- a/docs/assignments/week05.md

+++ b/docs/assignments/week05.md

@@ -1,13 +1,19 @@

# 5. E-Textiles and Wearables I

+##Results

+

+#IMAGE IMAGE IMAGE IMAGE

+

+* I made and documented a digital sensor using a bikini clip

+* I made and documented an analog sensor using Danish Kroner coins

+* I used hard/soft connections with conductive thread and perfboard, pushbuttons and conductive fabric.

+* I integrated the bikiniclip switch into a project: a choker that has an alarm system built-in.

+

+#VIDEO VIDEO VIDEO

+-------

-* Build at least one digital and one analogue soft sensors, using different materials and techniques.

* Document the sensor project as well as the readings got using the AnalogRead of Arduino

-* Integrate the two soft sensors into one or two textile swatches using hard soft connections

-* Document the circuit and it’s schematic

-* Document your swatches

* Upload a small video of the swatches functioning

-* EXTRA POINT Integrate the swatch into a project

## Basics, research, inspiration

@@ -15,13 +21,17 @@ I'm so excited about this week! I have worked with electronics before but have l

During this class I was in Copenhagen so I had to skip this assignment, but I'm catching up now. I had to miss some tutorials, but since I know electronics fundamentals from previous experience and [Fabacademy](https://fabacademy.org/archives/2015/eu/students/bogers.loes/06electronicsdesign.html), I mainly studied the (really helpful and clear!) materials provided by Liza Stark on the [class page](https://class.textile-academy.org/classes/week05/) and [Kobakant](https://www.kobakant.at/DIY/?cat=28). I've been obsessed with this website for years. It's so good.

-**Danish Krone Analog sensor by Plusea**

+**Danish Kroner Analog sensor by Plusea**

I found these swatches with the Danish Krone slide-switch/softpot by Plusea (Hannah Perner-Wilson) [here](https://www.instructables.com/id/Danish-Krown-Slide-Switch/). Since I was in Denmark this week, I kept a few of my Kroner to try it out!

+*Some Danish Kroner I kept from my trip this week.*

+

**Bikini clip digital switch**

-I went through my sewing kit looking for some textile related hardware that might be conductive. I found this nice bikini clip, check it with the multimeter and BOOM! Found my switch.

+I went through my sewing kit looking for some textile related hardware that might be conductive. I found this nice metal bikini clip, checked it with the multimeter and BOOM! Found my switch.

+

+*potential switches from my sewing box that didn't make the cut. Loes Bogers, 2019*

**Other learning yearnings**

@@ -33,8 +43,6 @@ I would like to try building and programming the circuit using an Atmel ATtiny85

I previously used some of the [open source Lilypad designs](https://www.sparkfun.com/lilypad_sewable_electronics) by Leah Buechley and recreated them in our lab. It would be nice to reuse some of those, like the TinyLily's I made - using ATtiny chips - with the sewing holes, or the one with the snap-on buttons, or the little LED lights I made with on-board resistors. Oh and I even made some battery clips that I could use now! Let's see. I also have some Lilypad components I bought, like this buzzer. Oooh I want to work with the buzzer as an output.

-![]()

-

*Tools we want*

And I found [this page](http://toolswewant.at/category/tools/) via the Kobakant website where soft circuiteers imagine and share ideas for tools they'd like to have for their practice! Ohhhhh man that is so inspiring! Because I'm not a designer, but I do have maker skills and affinity with these kind of practices I've been thinking about the option of making tools during this course. On this page there are so many ideas! Some of them are built already, others are just sketches.

@@ -74,7 +82,9 @@ It wasn't easy to sew in one continuous line without breaking the thread, but I

The tension between the threads should be equal so each thread keeps to its own side of the fabric :)

-[INSERT VIDEO]

+<iframe width="560" height="315" src="https://www.youtube.com/embed/sf6oPMbLPzo?controls=0" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

+

+*Prof. Pincushion on Youtube, explaining tension*

Sewing with the conductive thread was a lot harder to do! I didn't quite get the tension right but did sew a zig zag line which for testing purposes was enough. So I connected my multimeter, put it on the Ohm setting and put my Danish krone across to get some readings!

@@ -92,6 +102,7 @@ I found a new thread, barely got one stitch done....and then my machine broke. I

I found this metal bikini clip that I cut off a bikini once. It's really nice! My multimeter says I can use it (beep beep). Great! Off I go to prototype the digital circuit. Emma Pareschi, our electronics miracle worker at the Amsterdam lab provided us with the basic schematics that helped me quickly put together a circuit with a the digital switch and an LED. I'm not sure why she's opted for a pullup resistor here, maybe because the Arduino has an internal pullup so it's easy to switch between. But I'd say it makes more sense to use a pulldown that keeps the buttonState LOW unless pressed. I know you can change it in the code too, so whatever. But basically it would mean putting the resistor on the other end of the button, the one that connects to GND. @Emma can you explain why you use a pullup and not a pulldown? Does it matter?

+

##Building the digital circuit

###Using Arduino Uno

@@ -173,8 +184,29 @@ void loop() {

```

+<iframe width="560" height="315" src="https://www.youtube.com/embed/w8ZGU7MSt2Y?controls=0" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

+

+*The entire circuit prototyped with an Arduino Uno*

+

+

###Using an ATtiny85 DIP and Sparkfun TinyProgrammer

+**About the ATMEL ATtiny85 Microcontroller**

+

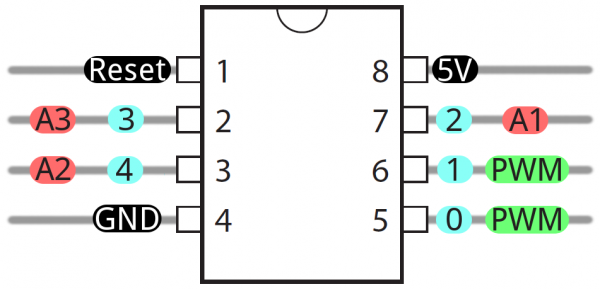

+There's many Attiny chips, and the 85 sits in a series with comparable chips: the ATtiny 25, 45 and 85. The 85 has the biggest memory (8Kb flash, 512 bytes of RAM, compared to 2Kb/128b for the 25 and 4kb, 256 for the 45). They have the same size

+

+The ATtiny85V has an operating voltage from 1.8-5.5, whereas the ATtiny85 (without V) has an operating voltage from 2.7V - 5.5V which means it will work when you power it with a power supply somewhere within that range. This makes it pretty good for e-textiles that you might want to power with a 3V coin cell, or a 3.7 LiPo battery. It consumes more power as you increase the clock speed, the 85 can run at 20mHz speed but also consumes more.

+

+Any version has a 1Mhz and 8Mhz clock built into the chip, but you can go 16 mHz or up to 20Mhz when using an external clock also called crystal (a small component you would have to add to the circuit to achieve a faster processing speed). You need higher speed for e.g. communication between boards. It supports two protocols that are common to have boards talking to each other: 1-SPI and 1-I2C. You could also make do with the lower ones for simple circuits, it's still pretty fast.

+

+More info and datasheet [here](https://www.microchip.com/wwwproducts/en/ATtiny85). Datasheets are a bit dry but are interesting to find out more about the chip: which pin can do what, if it has any internal pullup resisters you can use etc. For example, the datasheet gives this info on the pinouts and how to use the reset pin. It also details a technical drawing of the device with all measurements, this can be handy if you are designing your own traces that need to fit exactly with the chip.

+

+*ATtiny 25/45/85 pinouts as listed in the datasheet*

+

+It's important to know that these numbers are often NOT the same as the pin numbers you would call in Arduino. For that it's good to look up a tutorial page where they're often listed both alongside one another. Confusing but it is what it is.

+

+*Pinout image from the Sparkfun [hookup guide](https://learn.sparkfun.com/tutorials/tiny-avr-programmer-hookup-guide/attiny85-use-hints), the Arduino pin numbers are highlighted in turquoise. The red ones indicate which pins you can use for analogReads, the green ones (PWM pins can do pulse width modulation, for e.g. making sounds or fading LEDs.*

+

**Tools and instructions**

*Chips need programmers: Sparkfun's TinyProgrammer stick [Sparkfun's TinyProgrammer](https://www.sparkfun.com/products/11801)*

@@ -194,10 +226,12 @@ If you don't have a TinyProgrammer or are against buying hardware you can build,

*Programming an ATtiny with an Arduino-as-programmer*

-INSERT BIT FROM THE BOOK!

+The book Arduino Wearables:Stitch Your Way To Fashionable Electronics by Tony Olsson details a very comprehensive how to on programming an ATtiny with an Arduino Uno. I would recommend this book for a technical intro, the explanations are very clear. For imaginative and beautifully crafted projects I'd say Kobakant is absolutely leading but they don't explain all their swatches in as much detail. Using an Arduino board as a programmer can be useful because it doesn't require extra hardware to be bought or made! The overview below are a few screenshots from the book.

+

+*Section from the book Arduino Wearables by Tony Olsson, p. 285-288.*

-**Drivers and installs**

+**Drivers and installs for ATtiny boards**

I bought mine from Sparkfun years ago, they still have it. [This tutorial](https://learn.sparkfun.com/tutorials/tiny-avr-programmer-hookup-guide/programming-in-arduino) explains well how to set everything up so you can start programming the chip in Arduino.

@@ -213,11 +247,11 @@ The clock is how fast you let the chip run (the frequency or speed at which it c

**Disconnect everything before programming**

-I got a lot of errors when trying to program the chip while keeping the rest of the circuitry connected. I just deconnected everything to be sure. It might have been that the buzzer was creating a short (see more on buzzer below).

+You might get a lot of errors when trying to program the chip while keeping the rest of the circuitry connected. The pins you use to connect components to are the same pins that are being used to program the chip, so they might interfere with the uploading process.

**Connecting and programming the chip (orientation matters)**

-When moving the chip around always keep track of the orientation! There's a mark on the chip to tell you which side is up. See also Sparkfun tutorial.

+When moving the chip around always keep track of the orientation! There's a mark on the chip to tell you which side is which. See also Sparkfun tutorial.

**Prototyping and breadboarding with the chip (and the programmer)**

@@ -310,6 +344,9 @@ command. If it wasn't the issue then it's at least good practice.

Faulty wiring. I am shorting my circuit everything I connect the switch ends together because the switch is directly between VCC and GND. The + wire should be connected to VCC not directly, but via the 10K pullup resistor. Errrp my bad. This solved the issues though and I have a working circuit using the components I'd intended. Wahoo! Ready to start crafting it into a textile swatch or project.

+<iframe width="560" height="315" src="https://www.youtube.com/embed/ubQqr7vtk6Q?controls=0" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

+

+*The entire circuit with an ATtiny, powered via USB (5V), Loes Bogers, 2019*

###Powering the circuit

@@ -383,6 +420,8 @@ void note (int n, int octave) {

This is the schematic of the circuit I cobbled together. I ended up switching the buzzer from pin 1 to pin 4, which is located on the left side of the IC, because it allowed for an easier layout of the conductive traces. Translating a schematic into a working circuit with a breadboard and jumpers is known territory for me. Making a soft circuit on the other hand: super new! And really quite challenging that I had a lot of fun with and made sooooo many mistakes haha.

+*Schematic and first design sketches, Loes Bogers, 2019*

+

###Concept? Who said anything about a concept?

As I had to start thinking of the form factor I realized I really didn't have a concept to put these things together at all. I just wanted to work with these components I had lying around. But if you like a story: I made a pink choker that represents the way we use social media. We use it to present ourselves nicely and pretty to the world. It's clear for everyone that it's always passively watching us and capturing us in the background (the red light in the choker), but it's not until we try to take off this leash or try to leave social media that we get alarmed, and continuously nudged into going back into the walled gardens with nosey neighbours. But yeah to be honest: just wanted to explore these particular materials.

@@ -399,8 +438,7 @@ It took several iterations to figure out a way to lay out the traces without cro

**The actual prototype (with improv)**

And then there's reality. I thought I'd planned the design quite well but of course I had taken the hard-soft connections for granted with my previous electronics design experience haha. There are standardized connectors, headers and what not for *everything* in electronics world. They are so ubiquitous that they become invisible. So I had to do a little improvising along the way. I tried to limit the amount of hardware to embed. I could have used a battery clip but decided to try making a soft connector instead.

-PICTURE HERE

-

+*Front and back of the prototype put together. Left to right: clip to GND, battery pouch, detachable buzzer, IC socket and ATtiny, LED board (upside down, facing outward), pullup resistor, clip to sensorPin, Loes Bogers, 2019*

DRAWING HERE

**Final code of the circuit**

@@ -499,6 +537,12 @@ void note (int n, int octave) {

I used a piece of perfboard to make a socket for the IC. It has holes so is easy to sew onto the fabric. I went through the holes 5-6 times, which fills up the hole but still allows you to press the IC in nice and firmly making nice connections whilst being able to remove it easily if you want to reprogram it or replace it (or wash the garment). I saw similar techniques on Kobakant's [listings for hard/soft connections.](https://www.kobakant.at/DIY/?p=1272). The foam material is so thick that the legs don't pierce through on the other end, which is extra nice because it's invisible and I can keep the legs intact for programming.

+*Left: the IC socket and LED pcb, sitting next to a burn mark I'd made replacing the resistor with a jumper, middle: connection with the bikiniclip using a bit of conductive fabric, and right: detachable buzzer pad with push buttons. Loes Bogers, 2019*

+

+**Bikiniclip connections**

+

+I only figured out as I was sewing the bikini clips onto the pink foam that they would not make an electrical connection if I'd just attach them! Haha I needed the thread to somehow touch the clip, which it doesn't do with a standard seam. So I put a small strip of conductive textile inside the fold around the clip before stitching it to attach the clip. Connection sounds good so I'm happy.

+

**Detachable buzzer**

I made the buzzer detachable, using push buttons because this module gets damaged if you wash it according to the [Lilypad buzzer specs] (https://www.sparkfun.com/products/8463).

@@ -511,14 +555,14 @@ I was getting a lot of shorts because the pushbuttons of the pocket were touchin

I should have researched better and I would have found these [Twelve Ways To Hold Your Coin Cells at Kobakant!](https://www.kobakant.at/DIY/?p=7064). I will make one of these for the second part of the assignment and do it proper. A bit of additional research also led me to this tutorial ["How to Work With Conductive Fabric"](https://www.instructables.com/id/How-to-Work-With-Conductive-Fabric/) which is packed with how-to's and tips on everyting e-textile. I'd like to try making a swatch with traces from conductive textile instead of the stitching technique.

-**Bikiniclip connections**

-

-I only figured out as I was sewing the bikini clips onto the pink foam that they would not make an electrical connection if I'd just attach them! Haha I needed the thread to somehow touch the clip, which it doesn't do with a standard seam. So I put a small strip of conductive textile inside the fold around the clip before stitching it to attach the clip. Connection sounds good so I'm happy.

+ *Not the best solution, but an improvised one that works. Loes Bogers, 2019*

**Resistor and SMD LED on a tiny board**

I bent the legs of the resistor to make sewable loops. And I had made some tiny PCB's with an LED taken from the open source files of the [LED modules](https://www.sparkfun.com/products/13902) that you can buy as part of the lilypad line. You can find the schematic and design files under "documents", I modified them to match the components I had, milled and soldered them. What I'd forgotten was that I used these for a different purpose at the time 3 years ago. I had to do a lot of debugging before I realized there was a 1K resistor on the LED board. Which is HUUUUUGE for this circuit, and prevented the LED from lighting up. Also, the front and back of these boards are not connected, you have connect them if you want the front and back pads to be connected. Hahahahaha classic mistake. I undid all the stitches, removed the resistor and replaced it with an SMD 0Ω resitor that acts as a wire/bridge/conductor. And presto! Everything works.

+*The devil, the details: you know how it is. This is the LED board that was stitched on at the back an not making a connection to the front where the components were. Loes Bogers, 2019*

+

####Front-back-middle?

I spent quite some time thinking about the inside and the outside of the choker, but I would definitely look for more options in a next iteration. I decided to keep the components all on the inside, away from view, and just show the traces to the world. The LED lights up nicely coming from behind the fabric, it gets a bit diffused which I think is very nice. Of course my stitching needs to be way better for this to look nice.

@@ -531,11 +575,11 @@ Next time I'll only hand stitch sitting down with a glass of wine and a nice fri

For now: look at these stitches, they are not that bad! Don't look at the other ones please. I used a little rotary pointy tool to draw even dotted lines that helped with stitching in a regular rhythm. But still: Ceciia could you bring us your needlepointing bible?

-IMAGE OF TOOL

+*Left: me trying to sew on some pushbuttons neatly (tongue pressed between my lips and all), middle: me finding out that I sewed it on upside down....right: maybe this tool will save my traces? Loes Bogers, 2019.*

###Debugging tips and tricks

-Yeaaaasssss my favourite part haha. I get to practice my mindfulness and sense of humour here because this never goes as expected. I used to get so frustrated! Now I understand a little better that it's just part of the process and it's actually a nice puzzle somtimes. I was very hopeful it would work right away. Which is partially did. I was getting a buzzer, and it would stop as the clip connects. But I got a lot of shorts with the battery pocket, like I described (I *heard* weird sounds at times and *saw* that the LED was not turning on when expected. It took half a day to figure out why the LED wasn't coming on. It was because the top and bottom of the board were disconnected and I was connecting the back whereas the front has the components on them.

+Yeaaaasssss my favourite part haha. I get to practice my mindfulness and sense of humour here because this never goes as expected. I used to get so frustrated! Now I understand a little better that it's just part of the process and it's actually a nice puzzle somtimes. I was very hopeful it would work right away. Which is partially did. I was getting a buzzer, and it would stop as the clip connects. But I got a lot of shorts with the battery pocket, like I described (I *heard* weird sounds at times and *saw* that the LED was not turning on when expected. It took half a day to figure out why the LED wasn't coming on. It was because the top and bottom of the board were disconnected and I was connecting the back whereas the front has the components on them. Hot tip: *do not seal your connections with hotglue until everything works, it's impossible to probe your circuit with nailpolish or hotglue everywhere....*

If something is not working or behaving weirdly, I use these debugging strategies I learned from Emma during Fabacademy:

@@ -558,15 +602,67 @@ If something is not working or behaving weirdly, I use these debugging strategie

For example: I might try to connect a buzzer but am not sure how to connect it. In my code I'll write a command to play a note on the buzzer, and also turn on an LED. If the buzzer doesn't play a tone but the LED turns on I know that the program is running correctly and I probably have to look at the way I connect the component or how I drive it in the code. If there's no tone AND no light, it probably means the program never reaches that part of the code.

+

+**Ugh, despair. Why didn't I record the results right away?**

+I didn't document the working piece straight away when it was working. And when I tried to do it this evening. It was buggy again. More debugging for me :(

+

****

+##Building an analog needle felt squeeze sensor

+

+I had this conductive wool so started off making a sensor with that. I saw it [here](https://www.kobakant.at/DIY/?p=7795) first :)

+

+**The schematic**

+

+**Multimeter reading**

+Unstable reading of the dot but somewhere beteen 200-300ohm without squeezing, to totally conductive (beeeeeeep!) when I squeeze it. The kobakant tutorial suggest to mix in some normal wool to make it more resistive but I don't have that lying around so will just make do here for now but I can see how this would give me a rather limited range. So let's see how far we can stretch it.

+

+**Code: analogRead to serial**

+This difference in resistance reads on between 1000 and 1023 on the analogRead pushed to serial. It only occasionally drops below. So thats a pretty small spectrum.

+

+**Code: constrain() and map()**

+I map the 24 step range to a range of 0-255 (the range I can drive a LED with later, using pulse width modulation.

+

+**Code: analogRead to plotter**

+Can be handy because more visual. Use right syntax though.

+

+**Code: AnalogWrite or Pulse Width Modulation to fade LED**

+Sends it as a wave that we perceive as continous.

+

+**Code: smooth()**

+What does this do?

-##Building the analog circuit

+Array

+

+Average

+

+I used a delay of 100 milliseconds to be able to read the readings from the serial monitor more easily, but it made the LED fading jittery and it would fade away very slowly. Turning down the delay at the end to 50 milliseconds made it more responsive.

+

+###Wool dot swatch

+

+**Hard/soft connections**

+

+*The dot*

+One connection to GND via pulldown resistor, one connection to AnalogRead pin on side, and on the other side connected to VCC. So three connection point to connect this sensor swatch.

+

+*LED*

+I'm adding the LED because it's nice to be able to get feedback. And it's a very nice LED! One leg to a PWM pin, one to GND

+

+**Sketching a design**

+

+

+

+##Building another analog circuit

+

+Here are my Kroner! Sitting on a paper circuit sketch. I collected some very nice leather samples from the lab for making swatches now that I know my rolling pin is a leather wheel :) The basic swatch consists of a a conductive trace to VCC, a resistive trace going to a pin that can do an analogRead, and connected to GND via a pulldown resistor. The Kroner is the wiper hand that connects the two traces at a position you can adjust by sliding it along the traces.

+

+*Does this count as a schematic? ;) Loes Bogers, 2019*

###Using Arduino Uno

+

```

CODE CODE CODE

diff --git a/docs/assignments/week06.md b/docs/assignments/week06.md

index 19bd0ab56efdbaf60e472d8f6850cfab262057a8..4f1a3846ce70e66db7868306d989921d5df10ed5 100644

--- a/docs/assignments/week06.md

+++ b/docs/assignments/week06.md

@@ -501,7 +501,7 @@ I was a bit unsuccessful in making sheets so played more with blobs and things.

##Growing Mycelium or: surfing the Wood Wide Web

-In this crazy packed week, we also went back to the biolab where Maud and Sarah presented their work on growing Mycelium. Thanks girls! Really awesome research.

+In this crazy packed week, we also went back to the biolab where Maud and Sarah presented their work on growing Mycelium. Thanks girls! Really awesome research. Maud documents her process and findings on [this webpage](https://maudb.gitlab.io/dok/projects/grow-mycelium/).

**Mycelium basics: the Internet of the forest**

diff --git a/docs/images/wk05_arduinoasprogrammer.jpg b/docs/images/wk05_arduinoasprogrammer.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..4c396b0180df3ea4623e3482af8b1808e6fae4b3

Binary files /dev/null and b/docs/images/wk05_arduinoasprogrammer.jpg differ

diff --git a/docs/images/wk05_batterypouch.jpg b/docs/images/wk05_batterypouch.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..a8ba908f7bd3cf4c61560064d4710fa7b86a95c4

Binary files /dev/null and b/docs/images/wk05_batterypouch.jpg differ

diff --git a/docs/images/wk05_finallayout.jpg b/docs/images/wk05_finallayout.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..a0e922a8639cd4c08b997199d03934ea1e3f5b23

Binary files /dev/null and b/docs/images/wk05_finallayout.jpg differ

diff --git a/docs/images/wk05_hardsoft.jpg b/docs/images/wk05_hardsoft.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..52b9f49fad830935056e08ab271543d9a6b3ce5a

Binary files /dev/null and b/docs/images/wk05_hardsoft.jpg differ

diff --git a/docs/images/wk05_kroner.jpg b/docs/images/wk05_kroner.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..fe71c06742b22dd535ffb55d03876e8cb0e813db

Binary files /dev/null and b/docs/images/wk05_kroner.jpg differ

diff --git a/docs/images/wk05_kronerschematic.jpg b/docs/images/wk05_kronerschematic.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..c54c0dbf37950b6f1160767a8aa7e53255e953ee

Binary files /dev/null and b/docs/images/wk05_kronerschematic.jpg differ

diff --git a/docs/images/wk05_ledconnection.jpg b/docs/images/wk05_ledconnection.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..1f298724e1a90ba9034d473804002e5fefb0042b

Binary files /dev/null and b/docs/images/wk05_ledconnection.jpg differ

diff --git a/docs/images/wk05_pinouts.jpg b/docs/images/wk05_pinouts.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..53ca86eecb9f8ba6e17d0cb90bc7b37eb63cc633

Binary files /dev/null and b/docs/images/wk05_pinouts.jpg differ

diff --git a/docs/images/wk05_potentialswitches.jpg b/docs/images/wk05_potentialswitches.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..b4e68fcedf23f8563a97557ab46973bb0c031e9c

Binary files /dev/null and b/docs/images/wk05_potentialswitches.jpg differ

diff --git a/docs/images/wk05_rollingpin.jpg b/docs/images/wk05_rollingpin.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..cf42dccd314e51cc8b09deb32212846e97d9ff6d

Binary files /dev/null and b/docs/images/wk05_rollingpin.jpg differ

diff --git a/docs/images/wk05_schematictodesign.jpg b/docs/images/wk05_schematictodesign.jpg

new file mode 100644

index 0000000000000000000000000000000000000000..e5d79bc6a8bb1a33360991c06c9ef7c4b97a83f2

Binary files /dev/null and b/docs/images/wk05_schematictodesign.jpg differ